tec.nicum "Safety. Smart. Sustainable."

All-in-one services for machine safety

The demands on modern production facilities are increasing: safety, efficiency and sustainability must go hand in hand today. With the guiding principle "Safety. Smart. Sustainable." tec.nicum, the Schmersal Group's service division, shows how machine safety can be intelligently combined with digital technologies and practical implementation – for a sustainable industry.

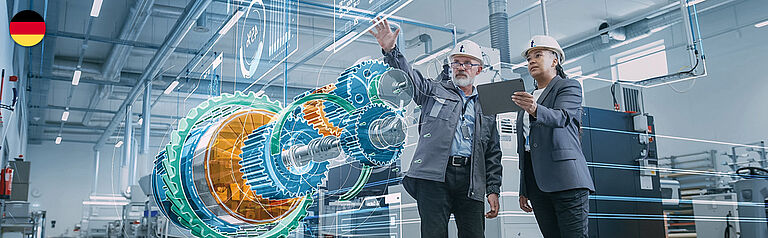

The focus is on AI-supported security monitoring, digitalised lockout-tagout processes and energy optimisation tools. The combination with augmented reality (AR) makes safety plannable and tangible - planning becomes visually tangible, investments transparent and costs clearly calculable.

Digital planning meets real implementation

"We are showing how digitalisation is redefining machine safety," explains Anton Ivanov, Head of Sales & Operations at tec.nicum GmbH. "By combining CAD technology, AR visualisation and AI-based analysis, we are increasing plant safety and minimising downtimes." The company relies on a turnkey approach: customers receive everything from a single source, from consulting and engineering through to implementation. Practical examples from real projects illustrate how companies can benefit in the long term – technically, organisationally and economically – from the combination of digital tools and security expertise. “Our goal: to make your processes more secure, efficient and future-proof - and to relieve our customers as much as possible in the process.”

One highlight is the integration of CAD technology with augmented reality (AR). This means that safety concepts and system layouts are not only visualised, but can also be experienced interactively. Investments become transparent and costs can be clearly calculated - even before the first move is made. The AR overlay on machines provides a glimpse into the future of safety and makes complex interrelationships intuitively understandable.

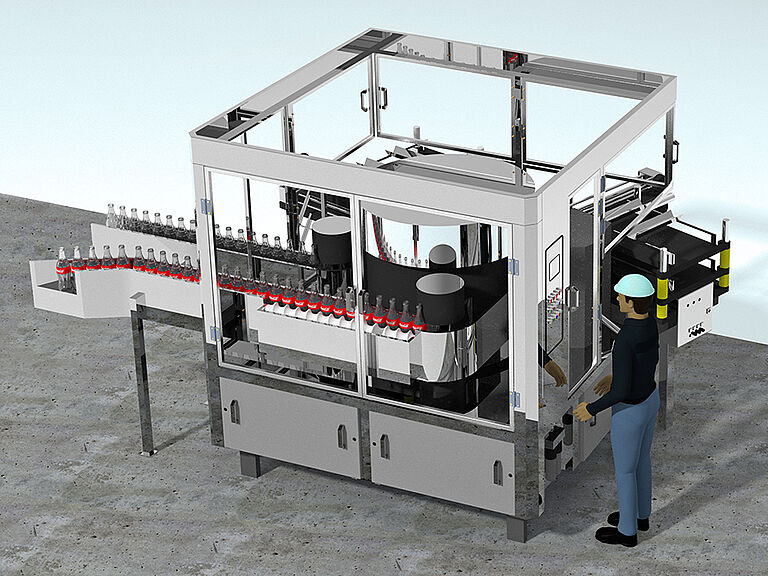

Turnkey approach for maximum relief – complete solutions from a single source

tec.nicum offers manufacturers and operators a comprehensive service: from consulting and engineering to implementation. Whether innovative engineering tools, 3D visualisations or customised processes - all services come from a single source. The result: safe, efficient and sustainable production solutions with minimal effort for the customer. The range of services offered by tec.nicum comprises six areas: academy (knowledge transfer), consulting (advice), engineering (technical planning), integration (execution and implementation), digitalisation (software solutions and new digital technologies) and outsourcing (complete solutions).